Macro tayo sare leh WE67K DSVP hydraulic160T 3200 CNC 4+1 DA66T mashiinka bireega saxaafadda

Hordhaca badeecada:

Matoorka servo ee mashiinka foorarsiga ee DSVP CNC wuxuu ku shaqeeyaa ku salaysan nidaamka xakamaynta servo. Waxay ka heshaa calaamadda amarka nidaamka CNC waxayna u beddeshaa calaamadda korantada dhaqdhaqaaq farsamo oo sax ah. Gaar ahaan, codeeyaha gudaha matoorka servo wuxuu dib u celin doonaa booska matoorka, xawaaraha iyo macluumaadka kale ee nidaamka xakamaynta wakhtiga dhabta ah si loo sameeyo koontarool xiran. Sidan oo kale, nidaamka xakamaynta ayaa si joogto ah u hagaajin kara wax-soo-saarka mootada iyadoo loo eegayo leexashada dhaqdhaqaaqa dhabta ah iyo amarka, si loo gaaro xakamaynta saxda ah ee dhaqdhaqaaqa mashiinka qalooca iyo hubinta saxnaanta iyo xasilloonida foorarsiga.

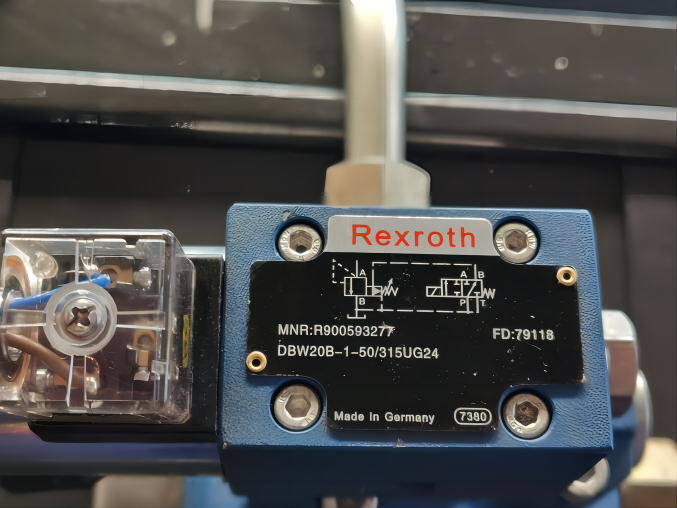

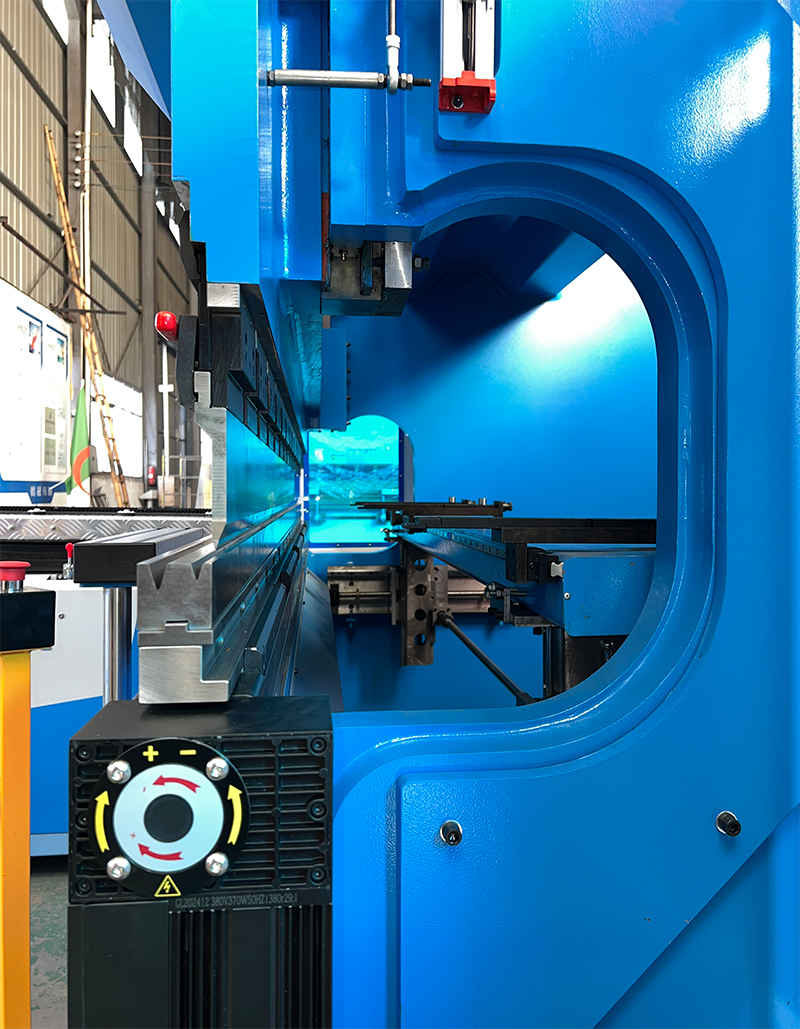

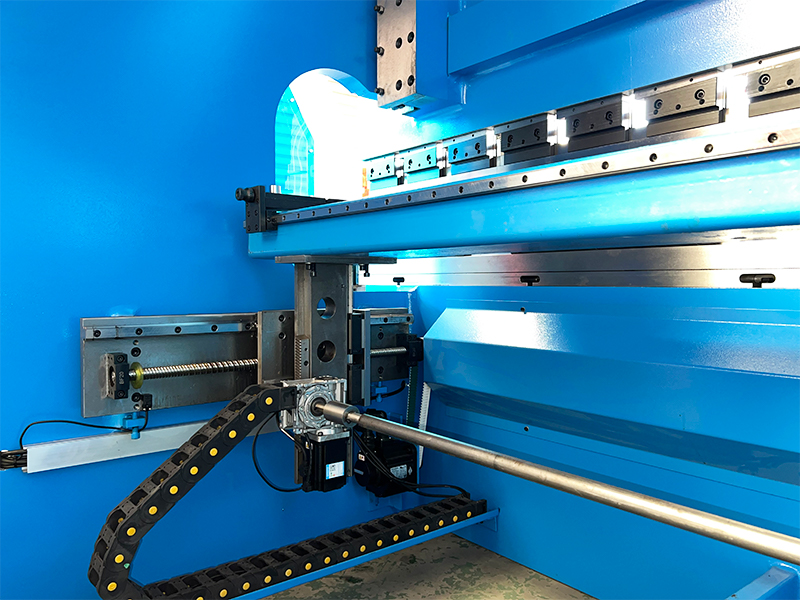

Waxay qabataa qaab dhismeedka alxanka guud waxayna ku qalabaysan tahay nidaamka xakamaynta tirada ee Delem DA66T oo sax ah. Waxay leedahay shaqada foorarsiga la isku daray oo ay fududahay in la shaqeeyo. Nidaamka hydraulic Rexroth ee laga keeno Jarmalka ayaa loo doortay si loo hubiyo xasilloonida shaqada ee sare ee mashiinka CNC-dabareegga. Habka magdhowga ee goobta shaqada waxaa laga dooran karaa magdhowga farsamada ama magdhowga haydarooliga, kaas oo hubinaya toosnaanta wanaagsan iyo xagasha foorarsiga shaqada ee la warshadeeyey. Kubbada kubbadda iyo hagaha toosan ayaa laga soo xulay Taiwan HIWIN qaabeynta dhamaadka-sare. Nidaamka xakamaynta tirooyinka ayaa si toos ah u hagaajin kara qadarka magdhowga, taas oo sahlan in la shaqeeyo oo leh nolosha mashiinka dheer.

Sifada alaabta

1.Tiknoolajiyada DSVP waxay si toos ah u hagaajin kartaa socodka wax soo saarka iyo cadaadiska bamka saliidda iyadoo loo eegayo culeyska shaqada dhabta ah ee mashiinka foorarsiga, kaas oo badbaadin kara qiyaastii 60% tamarta marka la barbar dhigo mashiinnada foorarsiga dhaqameed.

2.Since bamka bamka saliidda ee soo saarista tamarta dhabta ah waxay u dhigantaa culeyska dhabta ah, lumitaanka tamarta iyo kulaylka ayaa la dhimay, heerkulka saliidda ayaa hooseeya inta lagu jiro hawlgalka, iyo nolosha adeegga qaybaha hydraulic waa la kordhin karaa. Isla mar ahaantaana, qaylada qalliinka ayaa sidoo kale si weyn loo dhimay, taasoo bixisa jawi shaqo oo xasilloon.

3.High-xawaaraha sare iyo farsamaynta saxda ah: Qalabaynta nidaamka CNC ee horumarsan iyo tignoolajiyada xakamaynta servo, slider of DSVP CNC mashiinka foorarsiga si dhakhso ah u dhaqaaqo, si dhakhso ah u dhamaystiri kara hawlgalka qaloocin, iyo hagaajinta wax soo saarka. Iyo saxnaanta meelaynta waa mid sare, tusaale ahaan, saxnaanta meelaynta qalabka qaarkood waxay gaari kartaa ± 0.01mm, hubinta saxnaanta cabbirka iyo joogtaynta qaybaha la warshadeeyay.

4.Fully si toos ah CNC hydraulic press brake mishiinka leexiyo xaashida birta ahama birta ah, oo leh saxan foorarsan sare, hufan sare, shaqaynta fudud iyo badbaado

5.Qaabka welded ee mashiinka oo dhan wuxuu xaqiijinayaa saxnaanta sare iyo xasilloonida

6.Adopt Delem DA66T nidaamka hawlgalka muuqaalka, oo leh shaashad taabasho, hawlo badan oo la taaban karo, hawl fudud.

7.4 + 1 dhidibka CNC dhabarka, saxnaanta sare waxay gaari kartaa ± 0.01mm

8.With Invoance servo motor main, qaybaha korontada ee schneider ka France.

9.Ku rakiban birta hagaha toosan iyo kubbadda HIWIN, oo saxnaan sare leh, waxay gaari kartaa 0.01mm

10.Adopt nidaamka xakamaynta servo electro-hydraulic, oo leh waxqabad sare iyo saxsanaan sare

11.CNC Hydraulic Press Machine Brake Qalabka waxay isticmaalaan Qalabka 42CrMo, si loo hubiyo in ay ku dhintaan adkaanta, hubi in dhimashadu ay leedahay nolol dheer.

Codsiga alaabta

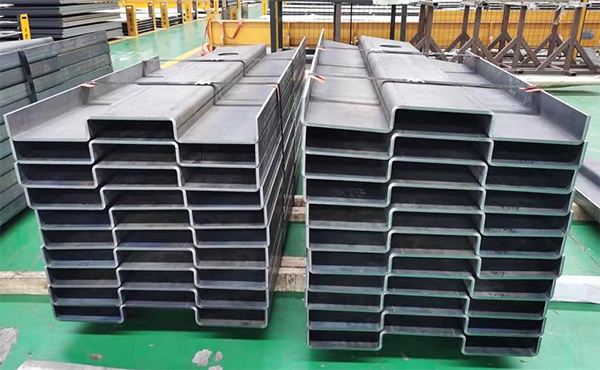

Cabbirrada iyo qaababka qaybaha qaab dhismeedka birta iyo qaybaha farsamada aad bay u kala duwan yihiin, taas oo u baahan awoodda wax-qabad ee sare iyo la qabsiga mashiinka foorarsiga. Waxay u baahan tahay inay awood u yeelato inay socodsiiso taarikada dhumucyada kala duwan iyo walxaha, oo ay hubiso xoogga iyo saxnaanta ka dib foorarsiga.

Waxaa loo isticmaali karaa in lagu soo saaro qaybaha isku dhafka ah ee birta birta ah iyo tiirarka birta ee dhismaha dhismayaasha birta, iyo sidoo kale goobaha shaqada, dhejiska, sanduuqyada, iwm ee wax soo saarka farsamada. Soosaarka cadaadiska xoogga leh iyo awoodaha xakamaynta saxda ah ee mashiinka foorarsiga ee DSVP CNC waxay si wax ku ool ah u leexin kartaa taarikada dhumucda leh iyo birta xoogga badan, buuxinta xoogga iyo shuruudaha saxda ah ee qaybaha dhismaha birta iyo warshadaha farsamada.

Halbeegga alaabta

| NO | Spec | Silinder Dhexroor dhululubo/dhexroor usha (mm) | bamka saliidda (ml/r)*2 | (Servo motor + darawalka)*2 | Dhaqso hoos Xawaaraha (mm/s) | Xawaaraha shaqada (mm/s) | Degdeg ahsoo noqoxawaaraha (mm/s) | Wcadaadiska ork (bar) | Awoodda haanta shidaalka(L) |

| 1 | 63T | 120/115 | 13 | 5.5KW | 250 | 25 | 250 | 275 | 50 |

| 2 | 100T | 151/145 | 16 | 7.5KW | 280 | 25 | 250 | 275 | 63 |

| 3 | 125T | 172/165 | 16 | 7.5KW | 180 | 15 | 180 | 270 | |

| 4 | 160T | 197/190 | 16 | 7.5KW | 160 | 12 | 160 | 255 | |

| 5 | 200T | 220/210 | 20 | 9KW | 130 | 13 | 140 | 263 | 80 |

| 6 | 250T | 240/230 | 20 | 9KW | 130 | 11 | 130 | 275 | |

| 7 | 300T | 260/250 | 20 | 9KW | 120 | 9 | 120 | 285 | |

| 8 | 400T | 310/295 | 32 | 15KW+22KW | 100 | 11 | 110 | 265 | 200 |

| 9 | 500T | 350/335 | 32 | 15KW+22KW | 100 | 7 | 90 | 260 | |

| 10 | 600T | 380/360 | 40 | 19.6KW+37KW | 100 | 8.5 | 80 | 265 | 300 |

| 11 | 800T | 430/410 | 50 | 31KW+37KW | 100 | 8 | 90 | 276 | |

| 12 | 1000T | 480/460 | 63 | 35.6KW+45KW | 100 | 6.5 | 80 | 276 | 400 |

| 13 | 1200T | 540/510 | 63 | 35.6KW+45KW | 100 | 6.5 | 60 | 262 | |

| 14 | 1600T | 630/600 | 100 | 60KW+75KW | 100 | 8 | 80 | 260 | 650 |

| 15 | 2000T | 700/670 | 125 | 72KW+90KW | 100 | 8 | 90 | 260 | |

| 16 | 2500T | 760/730 | 125 | 72KW+90KW | 100 | 6.5 | 80 | 275 | |

| 17 | 3000T | 835/800 | 160 | 90KW+110KW | 100 | 7 | 80 | 275 | 1000 |

| 18 | 3600T | 915/880 | 160 | 90KW+110KW | 100 | 6 | 80 | 275 |

Faahfaahinta alaabta:

Dhinaca dambe

Magdhaw makaanik

Xajin degdeg ah

Bosch Rexroth hydraulic valve

Bamka Haydarooliga ee Sunny

Golaha korontada

Delem DA66T CNC xakamaynta

Invoance Servo motor weyn

Standardtool(ikhtiyaar)

Kubadda maroojinta iyo hagaha toosan

Tusaale:

Xakamaynta ikhtiyaarka ah: